-

-

-

Flat Wire (0.05-0.35)*(0.5-6.0)

-

Strip/Foil (0.5-2.5)*(5-180)

Standard Compliant

Our production adheres to JIS G4313 standards, ensuring compliance with international quality benchmarks.

Equivalent overseas standards are listed for reference.

- ISO 80000, 15156 (NACE MR0175)

- IEC 60115-1, 60695

- ASTM A801/A801M, E1409

- EN E1409

- DIN 17175

- BS EN 10295

- SAE AMS 5524

- UL 746B

- JIS G4905, Z2371

- GB/T 1234, 10067.1-10067.3, 13304.1, 2820

Chemical Composition

| Grades | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 |

| Main Chemical Composition (%) | Chromium (Cr) | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Aluminum (Al) | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 |

| Other Additions | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune |

| Iron (Fe) | Rest | Rest | Rest | Rest | Rest | Rest | Rest |

| | | | | | Nb0.5 | Mo1.8-2.2 |

Physical & Mechanical Properties

| Grades | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 |

| Max. Service Temperature (°C) | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 |

| Resistivity at 20℃ (μΩ·m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 |

| Density (g/cm³) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 |

| Thermal Conductivity (KJ/m.h.ºC) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | -- |

| Coefficient of Lines Expansion (α×10⁻⁶/20~1000ºC) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 |

| Melting Point (°C) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 |

| Tensile Strength (N/mm²) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 |

| Elongation at Rupture (%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 |

| Variation of Area (%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 |

| Bending Frequency (F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 |

| Hardness (H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 |

| Continuous Service Time (Hours/ºC) | -- | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥50/1350 | ≥50/1350 |

| Micrographic Structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite |

| Magnetic Properties | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic |

Features

- FeCrAl alloy has a high melting point, typically above 1400°C, and can maintain stable performance at 1200°C for extended periods.

- At high temperatures, the aluminum in the alloy forms a dense aluminum oxide (Al₂O₃) protective film, which prevents further oxidation and enhances durability.

- The material exhibits low volatility and strong sulfur resistance, ensuring long-term stability while reducing material loss and replacement frequency.

- It has high resistivity with minimal resistance variation at elevated temperatures, making it highly suitable for heating applications.

- Compared to Nickel-Chromium alloys, FeCrAl alloy offers similar or superior performance at a lower cost, providing a more cost-effective solution for industrial heating applications.

Applications

- Industrial furnaces: Used as heating elements in melting furnaces, annealing furnaces, and other high-temperature systems

- Household appliances: Commonly found in ovens, heaters, and portable electric heating devices

- Far-infrared devices: Utilized for efficient heat radiation applications

- Nuclear engineering: Potential use in nuclear reactor components due to its high-temperature stability

- Additive manufacturing (3D printing): Ideal for high-temperature component fabrication in specialized manufacturing processes

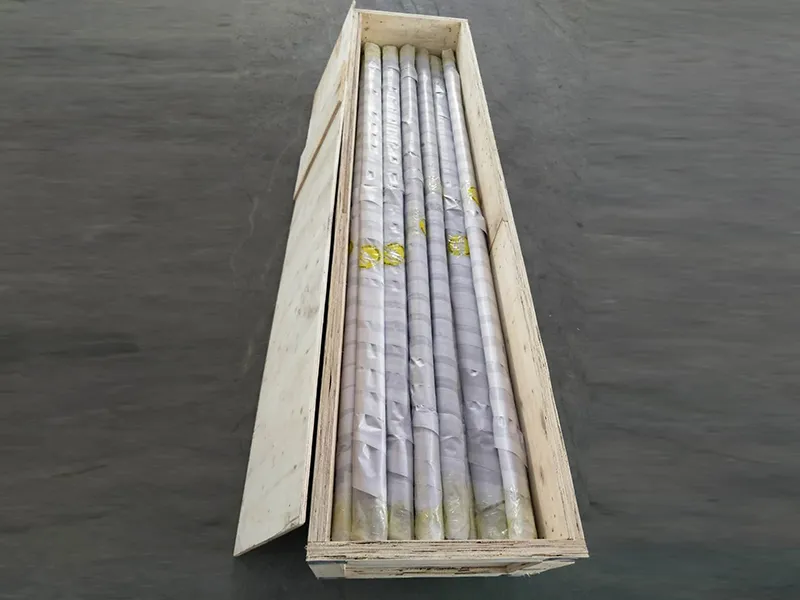

Packaging