-

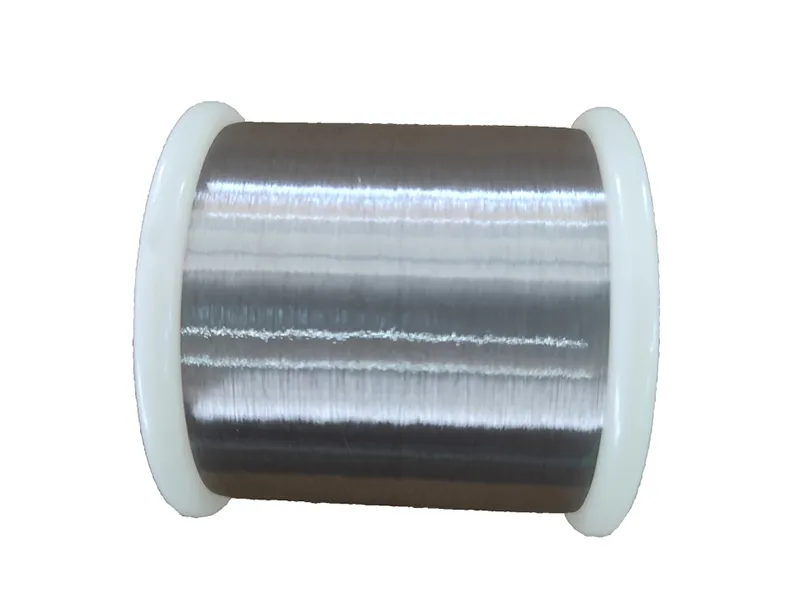

Wire

- Wire Diameter: 0.02mm-10mm

- Straight Wire: Length: 500mm-2000mm

- Surface Condition: Bright annealed, semi-hard, hard

- Tolerance: ±0.005mm-±0.05mm (depending on wire diameter)

-

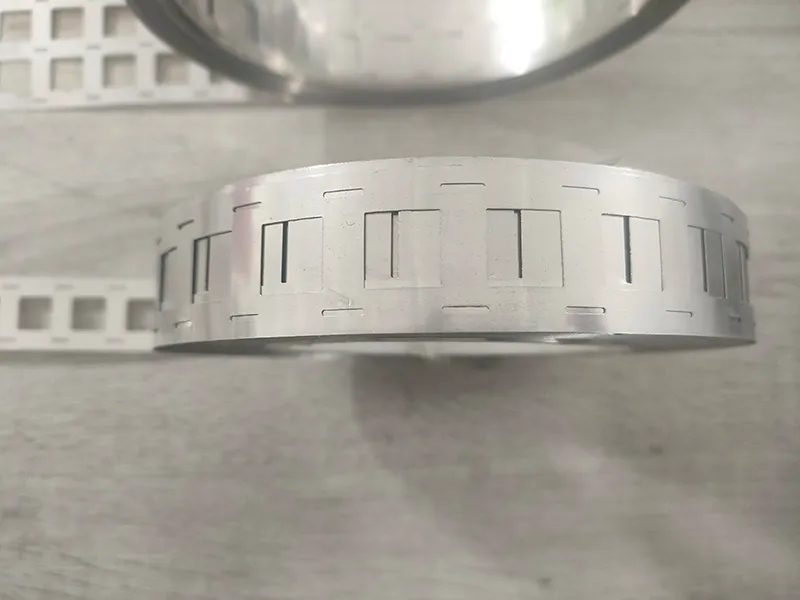

Strip

- Thickness: 0.01mm-3mm

- Width: 5mm-455mm

- Strip Roll: 100m-1000m/roll (depending on thickness and width)

- Hardness Condition: Soft, 1/2H, 1/4H, hard

- Thickness Tolerance: ±0.005mm-±0.02mm

- Width Tolerance: ±0.1mm-±0.5mm

-

Rod

- Diameter: 1mm-200mm

- Length: 100mm-3000mm, or customizable

-

Tube

- Outer Diameter: 6mm-300mm

- Wall Thickness: 0.5mm-20mm

- Length: 100mm-6000mm, or customizable

Standard Compliant

Our production adheres to JIS G4313 standards, ensuring compliance with international quality benchmarks.

Equivalent overseas standards are listed for reference.

Chemical Composition

| Grade | Nickel (Ni)+ Cobalt (Co) | Copper (Cu) | Silicon (Si) | Manganese (Mn) | Carbon (C) | Magnesium (Mg) | Sulfur (S) | Phosphorus (P) | Iron (Fe) |

| N4/Ni201 | 99.9% | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 |

| N6/Ni200 | 99.6% | 0.1 | 0.1 | 0.05 | 0.1 | 0.1 | 0.005 | 0.002 | 0.1 |

Physical & Mechanical Properties

| Grades | N4/Ni201 | N6/Ni200 |

| Density | 8.9g/cm³ | 8.9g/cm³ |

| Melting Point | 1455°C | 1445-1470℃ |

| Coefficient of Thermal Expansion | 13.0µm/m·°C | 13.3×10⁻⁶/℃ |

| Thermal Conductivity | 10.1W/m·K | 90.7 W/m·K |

| Electrical Resistivity | | 0.103×10⁻⁶Ω·/m (at 20℃) |

| Electrical Conductivity | 14.6% IACS | |

| Tensile Strength | ≥450MPa | ≥450 MPa |

| Yield Strength | ≥200MPa | ≥150 MPa |

| Elongation at Break | ≥40% | ≥40% |

| Hardness | ≤150 | |

Features

- Excellent electrical conductivity makes it ideal for use in electronic and electrical components

- Superior corrosion resistance performance in reducing environments, except in strong alkaline conditions

- Easily processed into complex shapes under hot or cold conditions with good weldability and formability

- Stable coefficient of thermal expansion for applications requiring temperature stability

- High-temperature strength & ductility maintains mechanical integrity even at elevated temperatures

- Some variants are shape memory alloys, allowing them to return to their original shape under specific temperature conditions

Applications

- Chemical & electroplating industry: Used in reactor vessels, pipelines, and corrosion-resistant equipment

- Electronics & battery industry: Found in lithium battery connectors, sputtering targets, and electrical contacts

- Aerospace: Applied in aircraft engine components and spacecraft parts

- Automotive manufacturing: Used in battery system components for electric vehicles

- Metal stamping & hardware: Ideal for high-strength and corrosion-resistant small components

- Telecommunications & vacuum electronics: Used in specialty bulbs, radio components, and vacuum devices

- Medical equipment: Selected for non-magnetic implants and surgical devices

- Diamond tools: Acts as a metallic binder to enhance durability and cutting efficiency

Packaging