-

-

-

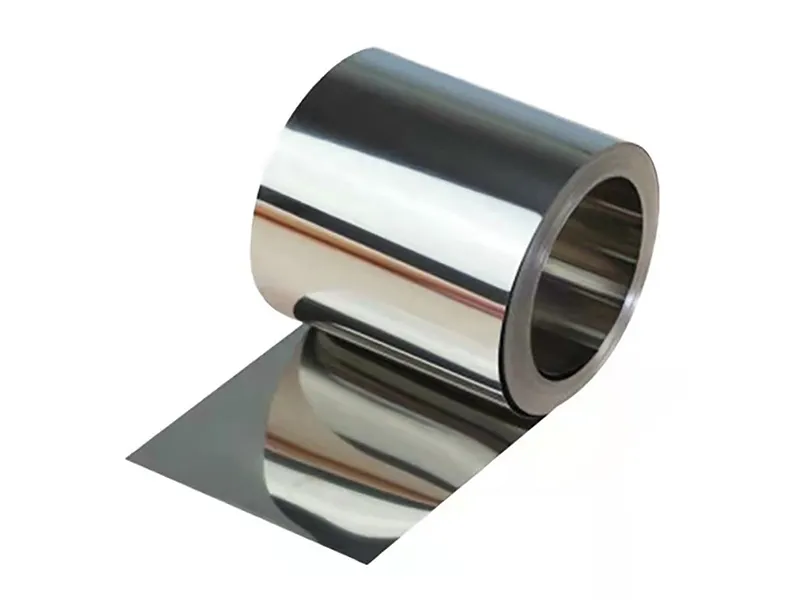

Flat Wire (0.05-0.35)*(0.5-6.0)

-

Strip/Foil (0.5-2.5)*(5-40)

Standard Compliant

Our production adheres to JIS G4313 standards, ensuring compliance with international quality benchmarks.

Equivalent overseas standards are listed for reference.

- ISO 6208, 15156

- ASTM B163, B166, B167, B168, B446

- DIN 17742, 17750

- AMS 5540, 5666

- GB/T 1234, 2077, 4437

Chemical Composition

| Grades | Cr10Ni90 | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni30 |

| Main Chemical Composition (%) | Nickel (Ni) | 90 | Rest | Rest | 55.0-61.0 | 34.0-37.0 | 30.0-34.0 |

| Chromium (Cr) | 10 | 20.0-23.0 | 28.0-31.0 | 15.0-18.0 | 18.0-21.0 | 18.0-21.0 |

| Iron (Fe) | -- | ≤1.0 | ≤1.0 | Rest | Rest | Rest |

Physical & Mechanical Properties

| Grades | Cr10Ni90 | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni30 |

| Max. Service Temperature (°C) | 1300 | 1200 | 1250 | 1150 | 1100 | 1100 |

| Melting Point (°C) | 1400 | 1400 | 1380 | 1390 | 1390 | 1390 |

| Density (g/cm³) | 8.7 | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 |

| Resistivity at 20℃ (μΩ·m) | -- | 1.09±0.05 | 1.18±0.05 | 1.12±0.05 | 1.00±0.05 | 1.04±0.05 |

| Elongation at Rupture (%) | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 |

| Specific Heat (J/g.℃) | -- | 0.44 | 0.461 | 0.494 | 0.5 | 0.5 |

| Thermal Conductivity (KJ/m.h.ºC) | -- | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 |

| Coefficient of Lines Expansion (α×10⁻⁶/20~1000ºC) | -- | 18 | 17 | 17 | 19 | 19 |

| Micrographic Structure | -- | Austenite | Austenite | Austenite | Austenite | Austenite |

| Magnetic Properties | -- | Non-magnetic | Non-magnetic | Non-magnetic | Weak magnetic | Weak magnetic |

Features

- Maintains mechanical stability at high temperatures between 1100°C - 1200°C, preventing deformation and structural degradation

- Forms a protective chromium oxide layer, preventing oxidation and surface degradation, making it ideal for extreme environments

- Provides high electrical resistance, making it suitable for electrical heating elements and resistance wires

- Ideal for applications where magnetic interference must be minimized, ensuring reliable performance in electronics and aerospace applications

- Remains ductile and easy to process, even after prolonged high-temperature exposure

- Withstands frequent temperature fluctuations, making it ideal for industrial heating systems and automotive exhaust applications

- Due to its high durability and minimal permanent elongation, NiCr alloy components retain their structural integrity over extended use providing longer service life

Applications

- Industrial & domestic heating systems: Used as heating elements in industrial and residential electric furnaces, including electric resistance wires and heating coils

- Aerospace components: Applied in aircraft engine parts and aerospace structural components requiring high-temperature durability

- Chemical & petrochemical processing: Resistant to corrosive environments, making it ideal for reactor vessels, pipelines, and processing equipment

- Electronics & electrical engineering: Commonly used in resistors, sensors, and other precision electronic components

- Automotive industry: Essential for turbochargers, exhaust systems, and other high-temperature components

- Medical equipment: Utilized in dental prosthetics (e.g., porcelain-fused-to-metal crowns) and orthopedic implants due to its biocompatibility and durability

- Nuclear engineering: Critical for nuclear power plant components exposed to extreme radiation and high temperatures

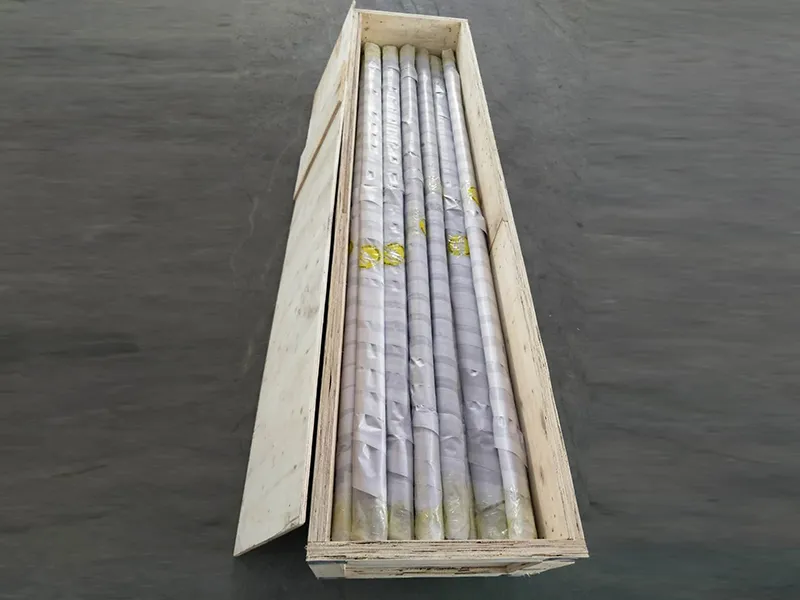

Packaging