-

Plate / Sheet

- Thickness: 1mm-100mm

- Width: 500mm-2000mm

- Length: 1000mm-6000mm

-

Rod

- Diameter: 5mm-500mm

- Length: 500mm-6000mm

-

Tube

- Outer Diameter: 6mm-250mm

- Wall Thickness: 0.5mm-30mm

- Length: ≤ 12000mm

-

Wire

- Diameter: 0.1mm-10mm

- Delivery Forms: Coiled wire or straight wire

Standard Compliant

Our production adheres to JIS G4313 standards, ensuring compliance with international quality benchmarks.

Equivalent overseas standards are listed for reference.

Chemical Composition

| Grades | Carbon (C) | Manganese (Mn) | Silicon (Si) | Sulfur (S) | Aluminum (Al)+Titanium (Ti) | Chromium (Cr) | Nickel (Ni) | Iron (Fe) | Copper (Cu) | Molybdenum (Mo) | Phosphorus (P) |

| Incoloy 800 | ≤0.1 | ≤1.5 | ≤1.0 | ≤0.015 | 0.3-1.2 | 19.0-23.0 | 30.0-35.0 | Rest | ≤0.75 | | |

| Incoloy 800H | 0.05-1 | ≤1.5 | ≤1.0 | ≤0.015 | 0.3-1.2 | 19.0-23.0 | 30.0-35.0 | Rest | ≤0.75 | | |

| Incoloy 800HT | 0.06-0.1 | ≤1.5 | ≤1.0 | ≤0.015 | 0.85-1.2 | 19.0-23.0 | 30.0-35.0 | Rest | ≤0.75 | | |

| Incoloy 825 | ≤0.05 | ≤1.0 | ≤0.5 | ≤0.03 | 0.8-2.2 | 19.5-23.5 | 38-46 | Rest | 1.5~3 | 2.5-3.5 | ≤0.03 |

| Incoloy 925 | ≤0.03 | ≤1 | ≤0.5 | ≤0.03 | 2.05-2.9 | 19.5-23.5 | 42-46 | Rest | 1.5~3 | 2.5-3.5 | ≤0.03 |

Physical & Mechanical Properties

| Grades | Density (g/cm³) | Melting Point (°C) | Tensile Strength (Rm N/mm²) | Yield Strength (Rp 0.2N/mm²) | Elongation at Break A5 (%) | Brinell Hardness (HB) |

| Incoloy 800 | 8.0 | 1350-1400°C | 550 | 210 | 35 | ≤363 |

| Incoloy 800H | 8.0 | 1350-1400°C | 450 | 180 | 35 | |

| Incoloy 800HT | 8.0 | 1350-1400°C | 500 | 210 | 35 | |

| Incoloy825 | 8.1 | 1370-1400°C | 650 | 300 | 30 | ≤230 |

| Incoloy925 | 8.14 | 1343°C | 650 | 300 | 30 | |

Features

- Highly resistant to chloride-induced stress corrosion cracking (SCC), pitting, and crevice corrosion

- Capable of prolonged operation in high-temperature environments while maintaining mechanical strength and oxidation resistance

- Maintains high tensile strength and ductility even at cryogenic temperatures

- Performs well in high-temperature oxidation and carburization conditions, retaining its physical properties over long-term exposure

- Easily welded, hot-formed, cold-formed, and machined, making it suitable for manufacturing complex components

- Non-magnetic or weakly magnetic, making it ideal for applications that require minimal magnetic interference

Applications

- Chemical & petrochemical industry: Used in reactors, heat exchangers, pumps, and valves

- Energy sector: Applied in steam generators, boiler tubes, and superheaters for nuclear and thermal power plants

- Marine engineering: Used in shipbuilding, subsea pipelines, and seawater desalination systems

- Aerospace industry: Found in aircraft engines and spacecraft components

- Automotive industry: Used in exhaust systems and turbochargers for high-temperature applications

- Food processing & pharmaceuticals: Utilized in processing and handling equipment

- Medical equipment: Suitable for MRI machines and non-magnetic instruments

- Oil & gas extraction: Applied in well casings, subsea production systems, and high-pressure components

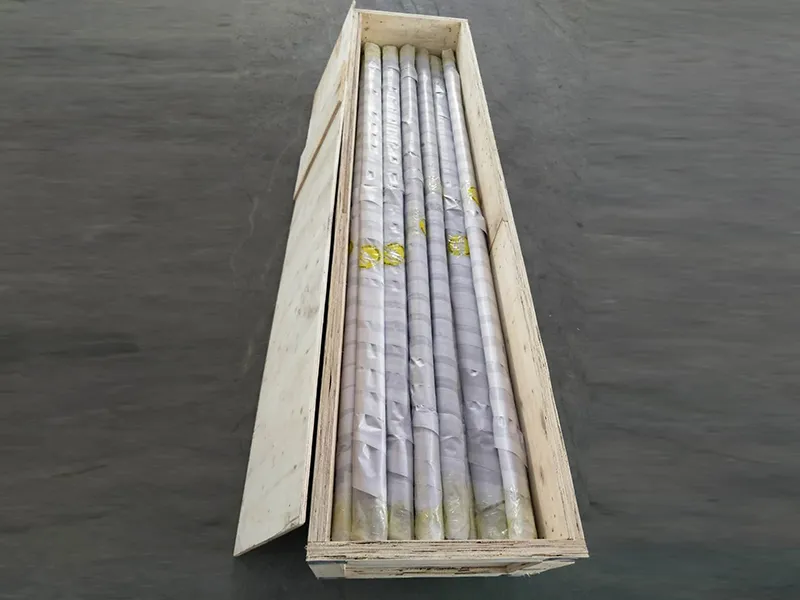

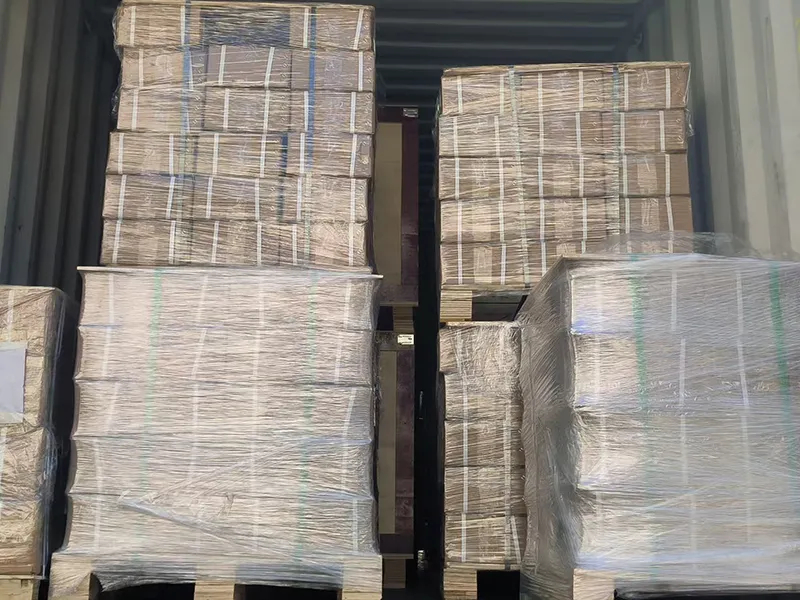

Packaging