Titanium alloys are a group of high-performance metals primarily composed of titanium, combined with other elements such as aluminum, vanadium, molybdenum, and iron. These alloys are well-known for their excellent strength-to-weight ratio, corrosion resistance, and ability to maintain mechanical properties at high temperatures. Therefore, titanium alloys are widely used in industries such as aerospace, automotive, medical, and industrial applications.

Available grade: TA1, TA2, TA15, TB5, TB6, TC4, TC9, TC11, TC21, GR1, GR2, Ti-6.5Al-1Mo-1V-2Zr, Ti-15333, Ti-1023, Ti-6.5Al-3.5Mo -2.5Sn-0.3Si, GR5, Ti-6.5AI-3.5Mo-1.5Zr-0.3Si, Ti-6AI-2.5Mo-2Nb-2, Sn-2Zr-1.5Cr-0.1Si and etc.

-

Plate / Sheet

- Thickness: 0.5mm-100mm

- Width: 1000mm-3000mm

- Length: 1000mm-6000mm

-

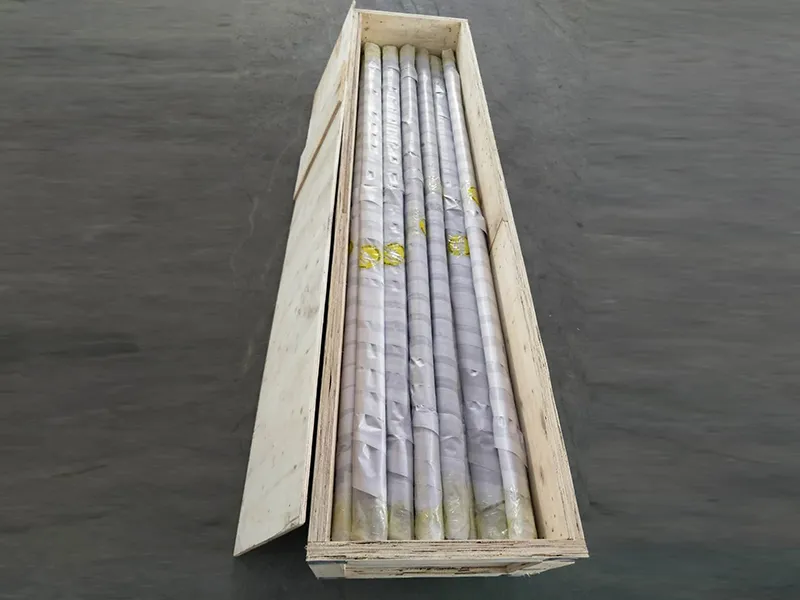

Rod

- Diameter: 5mm-400mm

- Length: 500mm-6000mm

-

Tube

- Outer Diameter: 3mm-300mm

- Wall Thickness: 0.3mm-20mm

- Length: ≤ 12000mm

-

Wire

- Diameter: 0.1mm-10mm

- Delivery Forms: Coiled wire or straight wire

| Titanium (Ti) | Aluminum (Al) | Vanadium (V) | Tin (Sn) | |

| Ti-6Al-4V | Rest | 5.5%-6.8% | 3.5%-4.5% | |

| Ti-5Al-2.5Sn | Rest | 4.5%-5.5% | 2.0%-3.0% |

| Density | 4.4-4.5g/cm³ |

| Melting Point | 1660°C |

| Coefficient of Thermal Expansion | 8-10×10⁻⁶/K (20°C-500°C) |

| Thermal Conductivity | 6-22 W/(m·K) (depending on alloy grade) |

| Electrical Resistivity | 0.14-0.17 μΩ·m |

| Tensile Strength | 600-1200 MPa (depending on alloy grade) |

| Yield Strength | 480-1100 MPa |

| Elongation at Break | 10%-25% |

| Hardness | 200-400 HB |

- Exceptional strength-to-weight ratio, providing lightweight materials without compromising strength

- Excellent corrosion resistance, particularly in seawater and other corrosive environments

- Non-toxic and hypoallergenic, making it ideal for medical applications

- Maintains good mechanical properties at temperatures up to 600°C

- Low thermal expansion compared to many metals

- High fatigue strength and toughness, even under repeated loading conditions

- Aerospace: Aircraft structural components, engine parts, satellite casings

- Marine engineering: Shipbuilding, subsea pipelines, seawater desalination units

- Medical devices: Bone plates, bone screws, artificial joints, and dental implants

- Automotive industry: Exhaust systems, suspension systems, connecting rods

- Sports equipment: High-end sports equipment such as bicycle frames, tennis rackets, and skis

- Chemical industry: Reaction vessels, heat exchangers, pump valves, and equipment exposed to strong acids and alkalis

- Energy industry: Cooling system components in nuclear power plants and thermal power plants

- Conatct: Hanna-DLX

- Email: chinadlx@dlx-alloy.com

dlxalloy@gmail.com

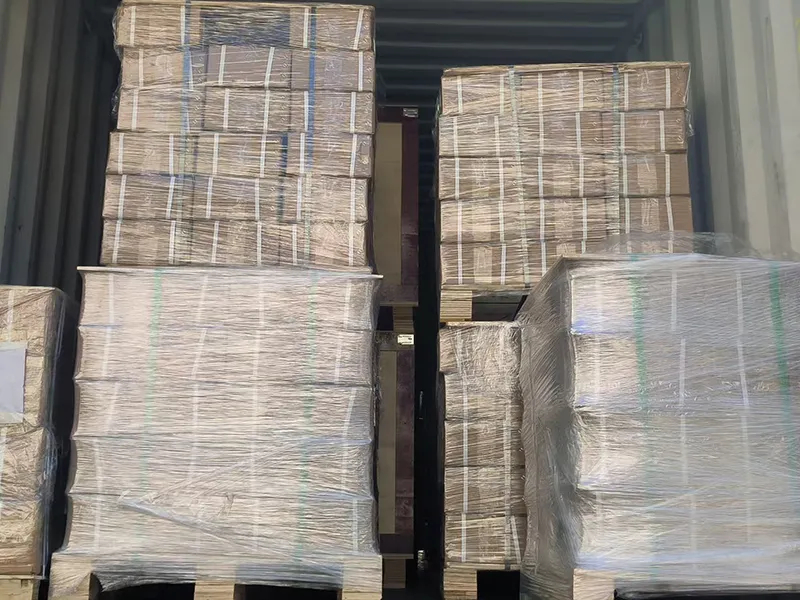

We offer a wide range of high-performance alloy products including electric resistance alloys, nickel alloys, titanium, copper, stainless steel and specialty alloys.

We offer a wide range of alloy products by form including rods, tubes, wires, strips, and more.