Cobalt-chromium tubes are high-performance metal tubes manufactured primarily from cobalt-chromium alloys, often alloyed with molybdenum, nickel, and tungsten to enhance their corrosion resistance, strength, and hardness. Known for their outstanding resistance to both acidic and alkaline environments, these alloy tubes also offer excellent mechanical strength and wear resistance. Their exceptional material properties make them a preferred choice for demanding applications across medical devices, aerospace systems, petrochemical processing, power generation, and precision engineering.

Available Grades: L605

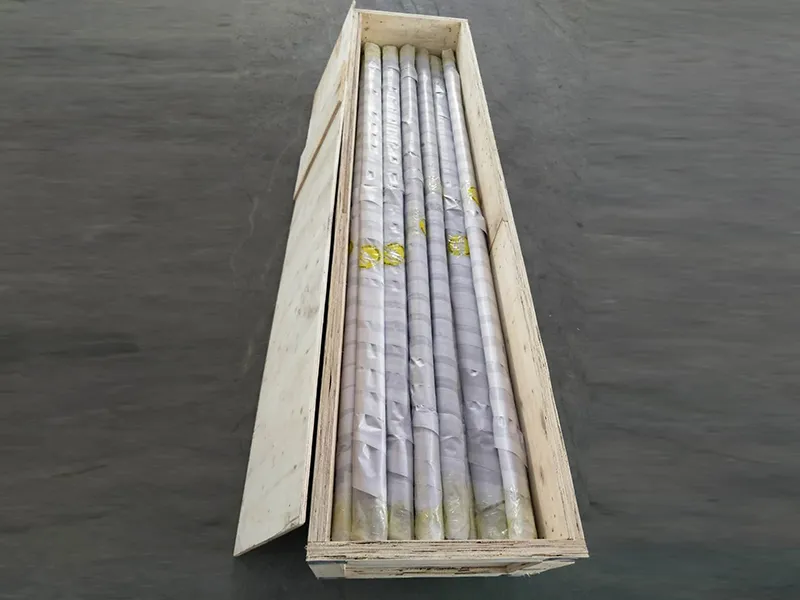

Outer Diameter: 6 mm - 150 mm, or customizable

Wall Thickness: > 5 mm, or customizable

Length: 100 mm and above (customizable)

| Density | 8.3-8.9 g/cm³ |

| Melting Point | 1310-1495 ℃ |

| Coefficient of Thermal Expansion (CTE) | 12.5-14.2µm/m·°C (20-250°C) |

| Thermal Conductivity | 14-69 W/m·K |

| Specific Heat Capacity | 20 J/kg·K |

| Hardness | HRC 30-55 |

| Tensile Strength | ≥700 MPa (e.g., medical-grade L605 in annealed condition) |

| Yield Strength | ≥550 MPa |

| Elongation | ≥3.0% - 15% |

- High tensile strength (≥700 MPa)

- Excellent machinability (annealed elongation ≥35%)

- Outstanding corrosion resistance (corrosion rate <0.01 mm / year)

- Good thermal and electrical conductivity (thermal conductivity: 12.3–23.9 W/m·K; electrical conductivity: ~20% IACS)

- Exceptional wear resistance (hardness: HRC 40–55; wear rate is only 1/10 that of 304 stainless steel)

- Strong creep resistance (retains high strength at 760°C)

- Medical: Used in coronary stents (e.g., L-605 alloy tubes), providing radial strength and promoting rapid endothelialization for vascular repair

- Aerospace: Applied in rocket engine nozzles serving as injector components capable of withstanding oxidation in liquid oxygen/kerosene flame environments

- Precision instruments: Utilized as thermocouple protection tubes, cobalt-chromium-tungsten alloy tubes resist vibration and wear at temperatures up to 1200°C

- Conatct: Hanna-DLX

- Email: chinadlx@dlx-alloy.com

dlxalloy@gmail.com

We offer a wide range of high-performance alloy products including electric resistance alloys, nickel alloys, titanium, copper, stainless steel and specialty alloys.

We offer a wide range of alloy products by form including rods, tubes, wires, strips, and more.