Brass

| Chemical Composition |

| Grade | Copper (Cu) | Zinc (Zn) | Lead (Pb) | Iron (Fe) | Antimony (Sb) | Bismuth (Bi) |

| H62 | 60.5-63.5 | Rest | 0.08 | 0.15 | 0.005 | 0.002 |

| H65 | 63.5-68.0 | Rest | 0.03 | 0.15 | 0.005 | 0.002 |

| Mechanical Properties |

| Grade | Tensile Strength (Rm N/mm²) | Elongation at Break A5 (%) | Thickness |

| H62 | 410-630 | 10 | 0.3-10 |

| H65 | 360 | / | 5-40 |

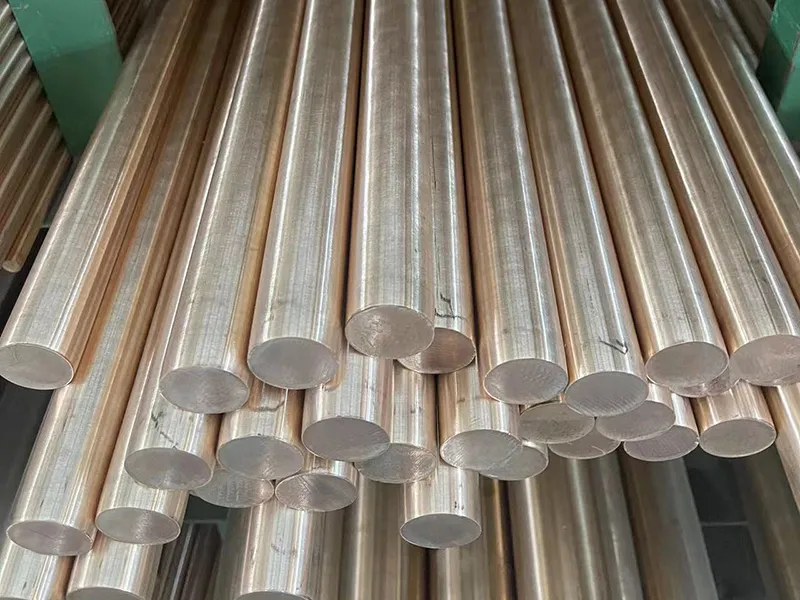

Beryllium Copper

| Chemical Composition |

| Grade | Beryllium (Be) | Nickel (Ni)+ Cobalt (Co) | Cobalt (Co)+ Nickel (Ni)+ Iron (Fe) | Lead (Pb) | Copper (Cu) |

| C17000 | 1.60-1.79 | ≥0.2 | ≤0.6 | - | Rest |

| C17200 | 1.80-2.00 | ≥0.2 | ≤0.6 | - | Rest |

| C17300 | 1.80-2.00 | ≥0.2 | ≤0.6 | 0.2-0.6 | Rest |

| Mechanical Properties |

| Standard | ASTM B196M/ASTM B441 | YS/T 334-2009 |

| High-Strength Beryllium Copper | C17000 | QBe2 |

| C17200 | Qbe1.9 |

| C17300 | Qbe1.9-0.1 |

| | Qbe1.7 |

| High Conductivity Beryllium Copper | C17500 | Qb0.6-2.5 |

| C17510 | Qb0.3-1.8 |

| | Qb0.3-1.5 |

Chromium Zirconium Copper

| Physical Properties |

| Density (g/cm³) | Tensile Strength | Hardness | Elongation at Break | Electrical Conductivity | Thermal Conductivity |

| N/mm² | HV | % | (20℃)IACS(%) | (20℃)W/m.k |

| 8.9 | ≥ 380 | 110-145 | ≥ 15 | ≥ 75 | 330 |

| Chemical Composition |

| Aluminum (Al) | Magnesium (Mg) | Chromium (Cr) | Zirconium (Zr) | Iron (Fe) | Silicon (Si) | Phosphorus (P) | Impurities |

| 0.1-0.25 | 0.1-0.25 | 0.1-0.8 | 0.1-0.6 | 0.5 | 0.5 | 0.1 | 0.5 |

Selection Criteria

- Corrosion resistance

Choose alloys with higher corrosion resistance for marine or outdoor environments, such as bronze and copper-nickel alloys

- Electrical/thermal conductivity

Pure copper or copper-silver alloys are ideal for applications requiring high conductivity

- Strength and durability

For structural applications, stronger alloys such as aluminum bronze or brass are preferred

- Machinability

For precision and large-scale manufacturing, leaded brass or machinable copper alloys are recommended for better machinability

Applications

- Electrical and electronics industry: Used in applications ranging from household wiring to large power transmission lines in power plants

- HVAC: Essential components like refrigerant piping, evaporators, and condensers

- Building and infrastructure: Roof materials, curtain walls, door and window frames, and other architectural features

- Automotive manufacturing: Engine cooling systems, brake systems, electrical wiring, and more

- Marine engineering: Components resistant to seawater corrosion such as ship hulls and propeller shafts

- Medical equipment: Surgical instruments, dental tools, and other medical devices

- Telecommunications: Copper shielding for fiber optic communication systems

- Instrument manufacturing: Used in brass wind instruments like trumpets and trombones

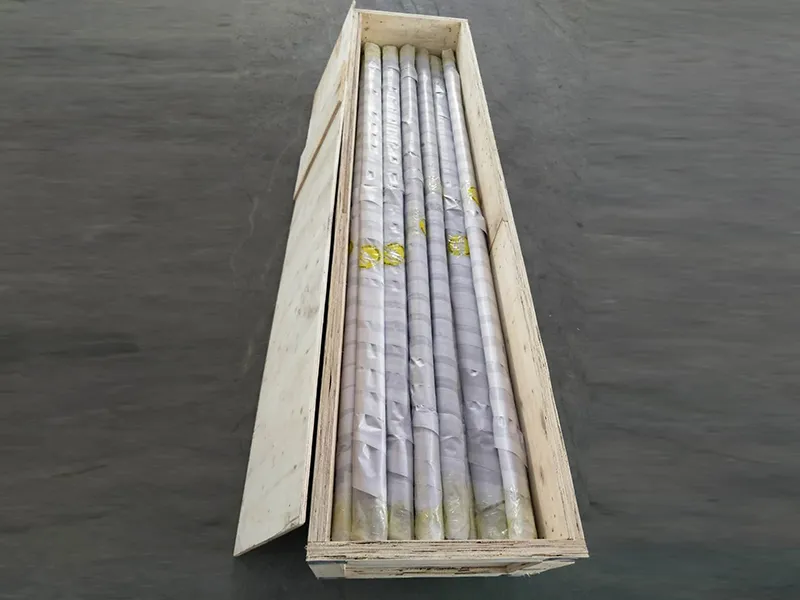

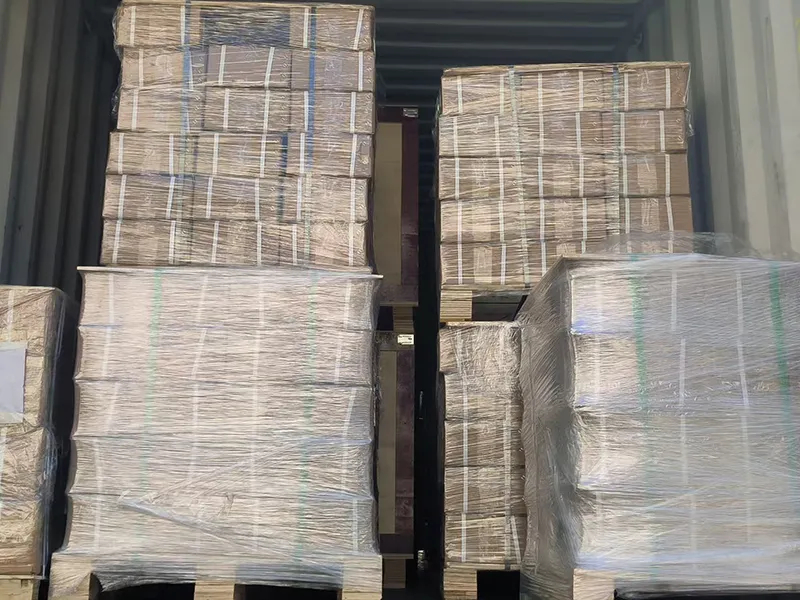

Packaging

Our Copper & Copper Alloy